100% AUTONOME - 1300 KG

The most compact autonomous mobile system in its category

This mobile decontamination unit is adapted to the new requirements specified in the terms of reference published by the INRS ED 6244 of 2020.

Intended for staff working at disassembly materials containing asbestos or lead.

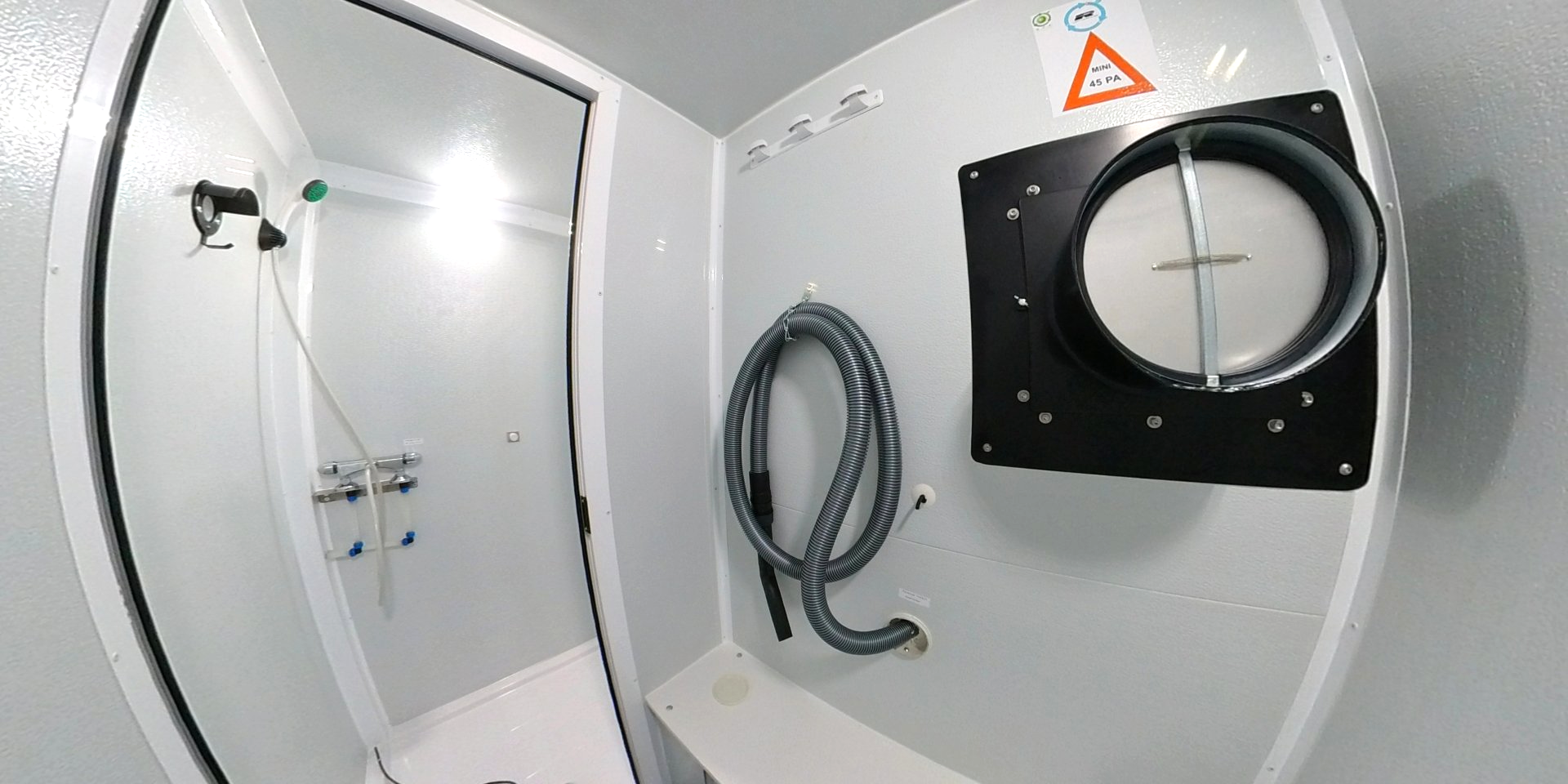

It has a decontamination tunnel 5 compartments equipped with 2 showers supplied with hot water, a waiting room, a spacious transitional room for undressing, a heated changing room with lockers and a separate technical room.

Continuous air filtration by negative pressure is ensured by the innovative R system control And R Cleaner developed by our team for the UMDs in the EVO range.

The showers have a wastewater filtrationwhich retains the asbestos particles, before sending the water to the sewer system.

The UMD EVO 208 (3.15m x 2m interior / 4.5m x 2m exterior) is entirely constructed of 30 mm sandwich construction (galvanized steel foam galvanized steel) which ensures a good insulation to the cold and to the heat.

Features:

Structure

- Constructed entirely from extruded aluminum profiles and 30 mm sandwich panels (galvanized steel foam galvanized steel)

- Galvanized chassis with one 1300 kg axle (ALKO) and overrun brakes

- 3 wheels of 195/50 R 13 (IC 900 kg)

- The AR pilots are recessed to prevent breakage during maneuvers.

- 4 stabilizing crutches

- 1 handrail on the access doors 1 pull-out step per access

- Honda engine petrol generator

- Reinforced 1600 kg tiller with jockey wheel

- GVWR: 1300 kg

Certified airflow assessment in accordance with the decree of April 8, 2013 and ED6244 2020

Interior configuration

- Opening and closing the automatic extractor hood

- Waste disposal hatch with bag or longopac system

- Filter drain access hatch from the hygiene shower

- Timer for switching off the extractor at the end of the shift

- Rest bench in the dirty airlock and the clean airlock

- Coat hooks in all the airlocks

- Rot-proof wooden flooring (marine plywood) covered with epoxy paint.

- 12V White LED Low Voltage Lighting

- 2 separate showers, each 1m x 0.80m

- 3 cabinets with hooks and 220V sockets

- Integrated 100L water reservoir

- 100L electric water heater

- 2 double filtration blocks for shower water drainage

- Polyester washbasin with hot and cold water, soap dispensers

- 2 diaphragm pumps with pneumatic control from the showers for wastewater drainage

- Fan heater (split) 2000 W

- NFC 15-100 electrical panel with 30 mA protection

- PEX plumbing

- Ventilation grilles to ensure perfect air circulation

- 600 m3/h extractor fan equipped with an H13 HEPA filter

- BEA "R Control" system for air circulation management

- Vacuum cleaner with THE filter

Key features:

- An oversized mechanism to protect your UMD:

- ALKO axle with a load capacity of 1,300 kg

- reinforced galvanized chassis

- low wheels

- load capacity of 900 kg per wheel

- braked drawbar and AL-KO coupling head with a towing capacity of 1600 kg

- Compact and 100% autonomous, it is widely used by roofing, earthmoving, industrial maintenance, and public works teams, without the drawback of a large decontamination trailer for moving around in urban or industrial environments.