Atelier de décontamination

Internalize the maintenance of your equipment, perform decontamination without confining your customers' space

The EVO X38 asbestos decontamination bungalow is specially developed for the internalization of the maintenance of asbestos removal equipment (extractors, vacuums, sanders, etc.) but also for the dismantling of asbestos or lead on industrial parts located on sites which do not allow the implementation of static containment.

Decontamination Unit suitable for personnel working on the dismantling of equipment containing asbestos, lead, chromium, carbon, nickel, etc.

It has a decontamination workshop and a decontamination tunnel (manufactured according to the specifications ED 6244 of April 2020) for operators equipped with 2 showers supplied with hot water, a spacious transitional room for undressing and a heated changing room with lockers.

THE permanent air filtration (H13 or H14) by depression is ensured by the innovative R system control developed specifically for EVO X38 decontamination units.

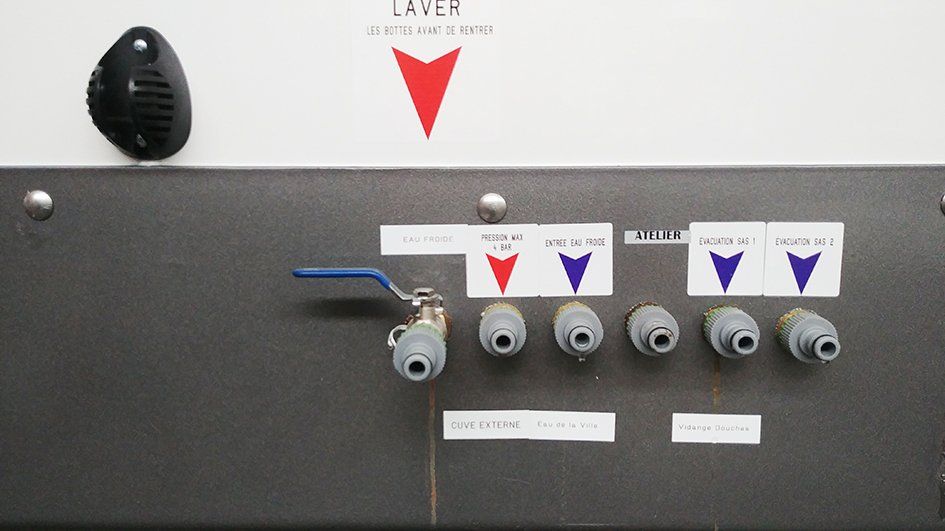

The showers and workshop have a wastewater filtrationwhich retains the asbestos particles, before sending the water to the sewer system.

Adapted to the new requirements, this model can incorporate a number of features and automated processes designed to strengthen the protection of operators as:

A generator with automatic switchover in case of power outage, a backup extractor fan with automatic switchover, a 200-liter water tank coupled with a high-pressure pump.

The EVO X38 bungalow is entirely constructed of aluminium profiles and 30 mm sandwich panels (polyester high density foam polyester) or 30 mm galvanized and lacquered steel sandwich panels, which ensures good insulation against cold and heat as well as high resistance to impacts.

Technical specifications:

Structure

- Hot-dip galvanized steel chassis, equipped with lifting points and 2 forklift pockets

- Passages for Manitou forks or other forklifts

- Constructed entirely from extruded aluminum profiles and 30 mm polyester sandwich panels or galvanized and lacquered steel sandwich panels. The polyester is coated with a white gel coat, providing a smooth, non-porous finish.

- Panels: assembled with aluminum profiles that ensure a self-supporting and solid structure. Weather and UV resistant.

- Empty weight: 2500 kg

- 4 leveling supports

- 1 SAS equipment 3 compartments connected to the workshop entrance

- 200L polyester water tank

- High-pressure pump with pressure switch for use with a water tank

- Self-illuminating guidance in case of power outage

- Ground-level water recovery system connected to the filtration system

- Stainless steel sink with mixer tap

- Rot-proof wooden flooring covered with a 10 mm layer of rubber. in the workshop to cushion the impact of falling heavy objects

- Air conditioning in the workshop (heating/cooling): Daikin AXB 25 or equivalent

- 1 rest bench with integrated water reservoir for safety in case of mains water outage

- 1 cabinet with Pramca generator, Honda S8000 engine with automatic start in case of mains power failure (optional)

- 12V White LED Low Voltage Lighting

- Two separate showers, each 1m x 0.80m. One filtration line per shower.

- 3 double (twin) aluminum cabinets with hooks and 220V sockets

- 150L electric water heater with electronic control or sealed gas water heater

- 3 double filtration blocks for water treatment

- 3 self-priming diaphragm pumps (17 l/min) connected to a double filtration system (25 µm 5 µm)

- 1. 500W heater in the technical room

- NFC 15100 electrical panel with 30 mA protection

- PEX plumbing

- Ventilation grilles to ensure perfect air circulation

- Extractor equipped with an HEPA H13 filter for normal operation of the unit (20 air changes per hour in the workshop)

- Extractor equipped with an H13 HEPA filter for backup mode and regulation in case of a drop in pressure

- 1 two-channel vacuum controller with printer audible alarm in case of vacuum drop in the workshop

- 1 EFM for automatic extractor speed variation

- BEA "R Control" system for management air circulation

- ATTIX 30-0H 30 l vacuum cleaner, class H

- External housing for the GE with anti-theft system (optional)

Certified airflow assessment in accordance with the decree of April 8, 2013 and ED6244 2020

Interior configuration

Key features:

- The workshop allows you to control the maintenance of your equipment and reduce its costs.

- The workshop is easily transportable on a platform or in a 20" container

- The workshop allows you to decontaminate industrial parts (valves, flanges, pipes etc.) on your client's site without installing static containment.

- Possibility of total self-sufficiency (in water and electricity).

- Effective insulation (for both heat and cold), and reversible air conditioning in the workshop allow you to work comfortably.

The EVO X38 decontamination bungalow is the model already adopted by the French armed forces; modern asbestos removal companies are equipping themselves in order to offer new services to their clients and to control the costs and maintenance times of their equipment fleet.